Understanding the Locking Handle

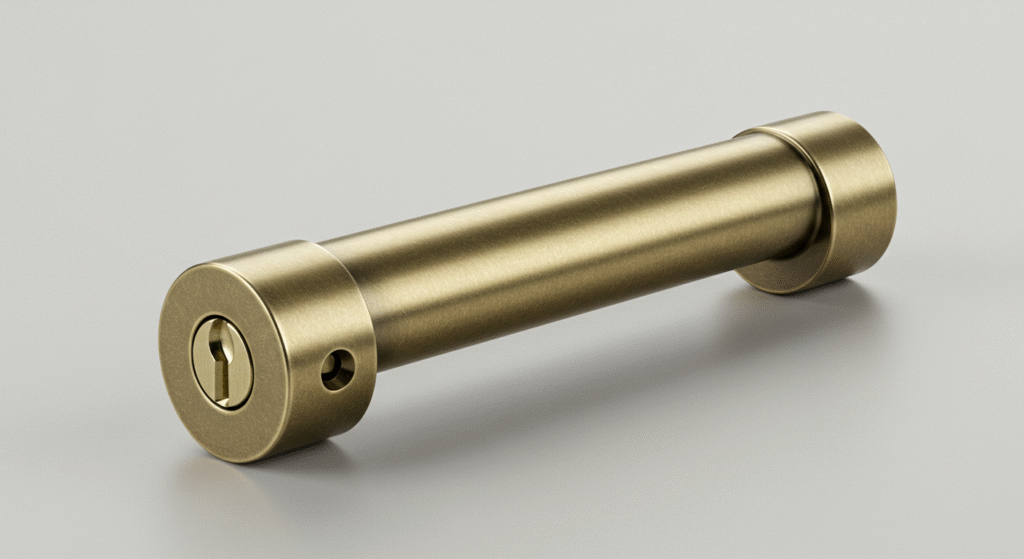

A locking handle is a vital component for securing doors, cabinets, windows, enclosures, and various access panels. Unlike a standard handle, a locking handle integrates a lock mechanism to restrict access and protect valuable contents. It combines convenience with security, offering a dual function that eliminates the need for separate locks and handles.

Whether it’s for industrial, commercial, or residential use, the locking handle serves an essential role in safeguarding property, equipment, and private spaces. Available in a wide variety of designs and materials, they cater to numerous applications where controlled access is necessary.

Types of Locking Handles

Locking handles come in several designs, each tailored to specific needs. Here are the most common types:

Swing Handles

Swing locking handles are typically used for electrical cabinets, control panels, and server enclosures. They provide high-security access with a robust locking mechanism and ergonomic design for ease of use.

T-Handles

T-handles are often found in vending machines, trucks, and industrial machinery. Their distinctive T-shape provides a strong grip, making them perfect for heavy-duty applications. Many T-handles feature key locks or padlock provisions.

Compression Handles

Compression locking handles offer a tight seal, often used in environments that require dust, water, or gas protection. They are common in HVAC units, marine equipment, and industrial enclosures.

Quarter Turn Handles

Quarter turn locking handles operate with a simple 90-degree rotation. They are widely used in control panels, switchboards, and light-duty enclosures. Their compact design makes them ideal for tight spaces.

L-Handles

L-shaped locking handles are popular for trucks, trailers, and storage boxes. Their practical design allows easy opening while offering strong locking capabilities.

And before you go, be sure to read through some of our other helpful posts!

Common Materials Used in Locking Handles

Choosing the right material for a locking handle is crucial depending on the environment and application. Here are some popular options:

Stainless Steel

Highly durable and resistant to corrosion, stainless steel locking handles are perfect for outdoor and marine applications. They maintain their appearance and functionality even in harsh conditions.

Aluminum

Lightweight yet strong, aluminum handles offer excellent resistance to corrosion. They are often used where weight reduction is critical without compromising strength.

Zinc Alloy

Zinc alloy locking handles are economical and versatile. They offer a good balance of strength, corrosion resistance, and aesthetic appeal, making them a popular choice for indoor applications.

Plastic

High-grade plastic locking handles are used where cost savings and lightweight features are needed. They are typically seen in light-duty enclosures and furniture.

Key Features to Look for in a Locking Handle

When selecting a locking handle, several features can greatly influence performance and user satisfaction:

- Security Level: Choose based on the level of protection needed. High-security models come with advanced locking mechanisms.

- Durability: Ensure the handle is built to withstand environmental factors such as moisture, dust, and temperature variations.

- Ease of Installation: Look for models that offer straightforward installation to save time and labor costs.

- Ergonomics: Handles should be comfortable to use and operate smoothly.

- Compatibility: Ensure that the locking handle fits the intended application and integrates well with the door or panel.

Applications of Locking Handles

Locking handles are extremely versatile and are used across numerous industries and applications:

Industrial Cabinets and Enclosures

Factories and plants use locking handles to secure control panels, machinery covers, and storage units. Protecting sensitive equipment is vital to avoid tampering and ensure operational efficiency.

Commercial Buildings

In offices, schools, and public institutions, locking handles safeguard confidential documents, valuables, and equipment stored in cabinets and lockers.

Residential Use

Homeowners use locking handles for doors, windows, toolboxes, and garden sheds to enhance security and privacy.

Automotive and Transport

Locking handles are critical in vehicles such as trucks, trailers, and service vans to secure storage compartments and cargo areas.

Medical and Laboratory Equipment

Hospitals, clinics, and laboratories rely on locking handles to protect sensitive equipment and hazardous materials from unauthorized access.

Benefits of Using a Locking Handle

The advantages of incorporating a locking handle into your setup are numerous:

Enhanced Security

A locking handle provides immediate and reliable security, preventing unauthorized access and protecting valuable assets.

Space-Saving Design

By combining the lock and handle into a single unit, locking handles save space and reduce clutter on doors and panels.

Improved Aesthetics

Modern locking handles come in sleek designs that enhance the appearance of enclosures, cabinets, and furniture.

Convenience and Efficiency

Users benefit from the simplicity of operation—no need to manage separate locks and handles. Everything is integrated into one easy-to-use unit.

Versatility

Locking handles can be adapted for countless uses, making them a flexible choice for both standard and specialized applications.

Expand your knowledge and check out more posts on our blog!

How to Choose the Right Locking Handle

Selecting the ideal locking handle involves several considerations:

- Application Environment: Indoor or outdoor? Exposure to moisture, chemicals, or extreme temperatures?

- Security Requirements: Basic deterrence or high-security needs?

- Material Preferences: Should the material offer corrosion resistance, strength, or lightweight properties?

- Budget Constraints: Choose a locking handle that fits your budget without compromising necessary features.

- Aesthetic Preferences: Depending on the application, appearance may be an important factor.

Installation Tips for Locking Handles

Correct installation is key to ensuring the effectiveness of a locking handle. Here are some general tips:

- Check Measurements: Ensure that the handle dimensions match the door or panel.

- Follow Manufacturer Instructions: Always adhere to the provided installation manual.

- Use the Right Tools: Use appropriate tools to avoid damaging the handle or door.

- Test the Handle: Before finalizing the installation, test the locking mechanism for smooth operation.

- Regular Maintenance: Periodically inspect and lubricate the handle to ensure longevity.

Maintenance and Care for Locking Handles

To maintain the effectiveness and appearance of your locking handles, regular care is essential:

- Clean Regularly: Wipe with a damp cloth to remove dirt, dust, and grime.

- Lubricate the Lock: Use appropriate lubricants to keep the locking mechanism functioning smoothly.

- Inspect for Wear and Tear: Look for signs of corrosion, damage, or malfunction and address them promptly.

- Replace Worn Parts: If the handle or lock shows significant wear, replace it to maintain security.

Future Trends in Locking Handle Technology

As technology evolves, locking handles are also undergoing significant advancements:

- Smart Locking Handles: Integration with electronic systems for keyless entry and remote access is becoming increasingly popular.

- Biometric Security: Some locking handles now incorporate fingerprint recognition for an added layer of security.

- Sustainable Materials: Manufacturers are focusing on eco-friendly materials to reduce environmental impact.

- Enhanced Ergonomics: Future designs will offer even better usability, especially for those with physical limitations.

Conclusion

Locking handles play a crucial role in securing access to various spaces, equipment, and assets. Their ability to combine convenience with security makes them indispensable across multiple industries and applications. Whether you need a locking handle for an industrial enclosure, residential cabinet, or vehicle storage box, understanding the different types, materials, and installation tips will ensure you make the right choice. Prioritize quality, functionality, and durability to invest in a locking handle that will serve you reliably for years to come.

FAQs

What is a locking handle?

A locking handle is a device that combines a handle with a locking mechanism to secure doors, panels, and enclosures.

Where are locking handles commonly used?

They are used in industrial cabinets, commercial buildings, residential doors and cabinets, vehicles, and medical equipment.

Can locking handles be used outdoors?

Yes, many locking handles made of stainless steel or treated aluminum are designed specifically for outdoor use.

How do I choose the best locking handle?

Consider factors such as security needs, environmental conditions, material preferences, and budget.

Are smart locking handles available?

Yes, smart locking handles that use electronic keypads, RFID, or biometric sensors are becoming increasingly popular.

Looking for more helpful tips and ideas? Check out our other articles on a variety of topics.