The control Cabinet Cooling supervise and power automation, process control, as well as digital communication in almost every industrial operation today. These cabinets not only house sophisticated electrical and electronic devices like PLCs, HMIs, drives, and circuit breakers, but also protect them. Ensuring equipment longevity and performance is particularly critical for automation settings that are harsh, with exposure to dust, corrosive elements, and extreme temperatures.

Here, control cabinet cooling systems make a difference. These systems act by reducing the risk of thermal damage to the components by regulating the internal temperatures and minimizing downtime, which increases efficiency at work. Among various technologies used in these systems, the waterproof fan is undoubtedly the toughest and is an essential component to cooling in harsh industrial conditions.

The purpose of this article is to describe the operation and advantages of control cabinet cooling solutions along with system selection for extreme environments.

The Importance of Cooling in Harsh Industrial Environments

Automation systems in manufacturing, energy, mining, oil and gas, and other heavy industries often face extreme conditions. Control cabinets, which are usually put adjacent to or within the operational zone, endure constant:

- Exposed to exceptionally high temperatures.

- Exposure to Dust, Particulate Matter, and Filth Containing Shredded Metal or Shaving Bits.

- Humidity due to washing activities of the surroundings or their weather conditions.

- Exposé to Chemical Smokes and Corrosive Gassing.

- Swaying Electrical Power Supply and Thermal Energy Demand.

These factors without an efficient cooling mechanism can result in violent overheating, condensation, electric shorts, or even parts wearing out before their expected time. Correctly designed control cabinet cooling systems mitigate such circumstantial consequences by providing seamless and uninterrupted performance automation by variable environment control.

Take the example of an outdoor environment that gets wet. There, a waterproof fan must be used to allow airflow without compromising the integrity of the enclosure.

Classifications of Control Cabinet Cooling Systems

Appropriate cooling technology selection depends on the application heat load, placement of the enclosure, and the surrounding environmental conditions. The following are some of the widely accepted types in industrial use:

Filtered Fan Units with Waterproofing Capabilities

For enclosures where the internal temperature is to be maintained at slightly lower than ambient temperature, filtered fan units serve as economical solutions. The addition of a waterproof fan extends application to outdoor and wet environments where protection against moisture ingress is critical while airflow is still maintained.

Air-to-Air Heat Exchangers

With these closed-loop systems, outside air is prohibited access to the cabinet, making them suitable for dusty or humid locations. They employ internal and external air flow paths separated by a heat exchanger core for thermal transfer.

Air Conditioners For High Ambient Temperatures

Air conditioning units are used when the ambient temperature is greater than the desired internal temperature of the cabinet. These are ideal for cabinets placed directly under the sun or close to high heat generating equipment.

Thermoelectric Cooling Systems

Thermoelectric coolers utilize the Peltier effect hence they are compact and efficient solutions for precise temperature control in small or isolated cabinets. With no moving parts, they are maintenance free and perfect for remote installations.

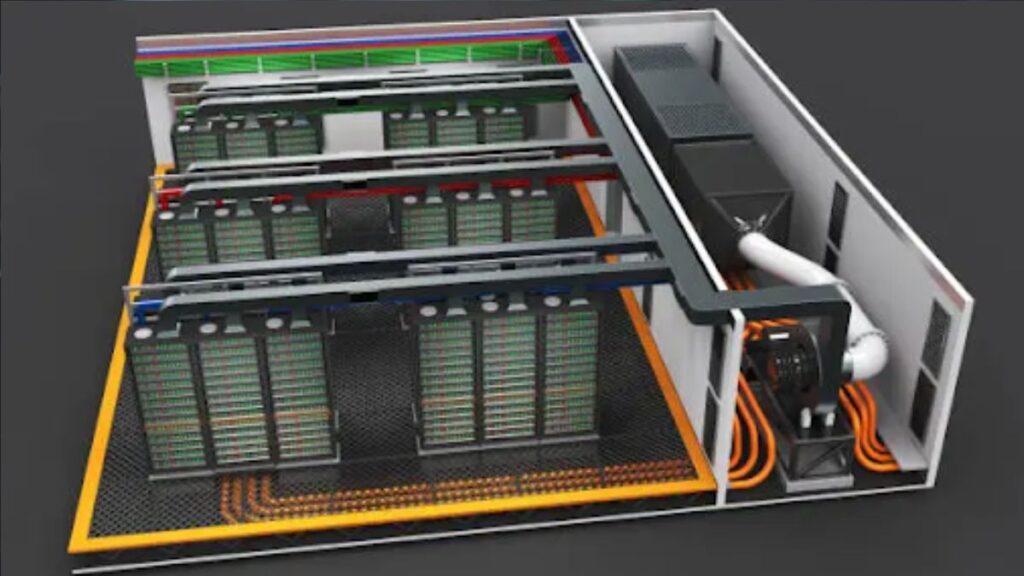

Cooling Using Liquids

Liquid cooling systems are particularly useful when air cooling is inadequate for critical cooling infrastructure systems or high-density electronics, as they provide superior thermal management. These systems are not as common but are essential to highly specialized environments.

Integrating robust elements, such as a waterproof fan, further improves function and reliability with these systems.

Improved Control Cabinet Cooling System Benefits

The control cabinet cooling systems must be adequately designed and implemented as they provide the organization additional operational and strategic benefits in extreme industrial environments.

Longer Lifespan of Equipment

High temperatures exerted on electronic components such as drives, controllers, relays, tend to be the most critical factor in their obsolescence. Efficient cooling assures virtually extend the service life of the components through proper maintenance.

Increased Operational Uptime

Unscheduled downtime comes with a dire cost in both operational efficiency and revenue. Effective cooling solutions reduce risk of overheating and increase servicing intervals to ensure a smooth workflow.

Environmental Protection

Cabinet cooling systems, especially those with sealed enclosures and configured with a waterproof fan, protects against environmental pollutants like dust, oil mist, and humidity.

Compliance with Industry Standards

Most industrial activities are subject to very strict safety and reliability regulations. Proper cooling systems help meet compliance requirements for parts dealing with enclosure construction, ingress protection (IP), and thermal control regulations.

Energy Efficiency

The latest cooling systems come with smart controls and energy efficient features which significantly reduces energy consumption. Throttling controls and variable speed fans enable the system to dynamically respond to real-time heat load.

Choosing a Cabinet Cooling System: Considerations

While designing a cooling system for your automation cabinets, do take into consideration these factors for optimal performance, robustness, and expandability.

Setting and Internal Temperatures

Evaluate the maximum expected external ambient temperature against the desired internal cabinet temperature. This evaluation will aid in deciding whether active cooling such as an AC unit, or passive/filtered solutions are needed.

Environmental Exposure

If the cabinet will be exposed to water, dirt, chemicals, or any other corrosive substances, you will require high-IP rated enclosures and a water-resistant fan to maintain protective airflow.

Heat Load

Estimate the required heat dissipation considering the total power consumption of the equipment inside the cabinet. To this end, several manufacturers offer heat load calculators.

Enclosure Dimensions and Arrangement

The overall dimensions of the cabinet along with the arrangement of components inside it influence airflow within the cabinet. This needs to be considered when selecting fan sizes, ducting paths, or heat exchangers.

Monitoring and Upkeep

Keep in mind the ease of access to the unit for maintenance like filter changes and fan replacements. Some more advanced systems might have temperature and humidity sensors and can be monitored or checked remotely.

In a number of industrial plant settings, finding control cabinet cooling systems with advanced intelligent sensors and sturdy components such as the waterproof fan could be the defining factor between uninterrupted productivity and expensive downtimes.

Upcoming Innovations in Control Cabinet Cooling

The rise in automation and smart manufacturing techniques is equally fostering new developments in thermal management. Here are some of the developments marking the future of control cabinet cooling systems:

- IoT Integration: Cooling issue detection is becoming more anticipatory thanks to real-time data and predictive analytics, making IoT technologies assist maintenance personnel actively.

- Smart Fans: Passive temperature regulation improves efficacy as well as noise reduction by changing fan speed based on temperature.

- Environmentally Responsible Construction: The focus is shifting for manufacturers to sustain the low power cooling technology and construction of the unit using recyclable materials.

- Cooling Functions Modular Units: Set expansion options are becoming more popular within industrial design to accommodate evolving infrastructure requirements.

With the increasing tightening of environmental regulations, rugged areas fully automated, systems will be even more vital equipped with features like the waterproof fan.

Conclusion

In critical industrial settings, maintaining the right temperature goes beyond comfort to include business continuity, safety, and uninterrupted operations. The control cabinet cooling systems safeguard the “heart” of industrial automation during extreme conditions when heat, dust, and moisture pose continuous risks.

Opting for a cooling solution with a waterproof fan and other ruggedized features helps guarantee system resilience, energy efficiency, and protection against harsh environmental factors. For organizations striving to improve uptime while minimizing maintenance and protecting automation systems, the correct strategy towards cabinet cooling is paramount.