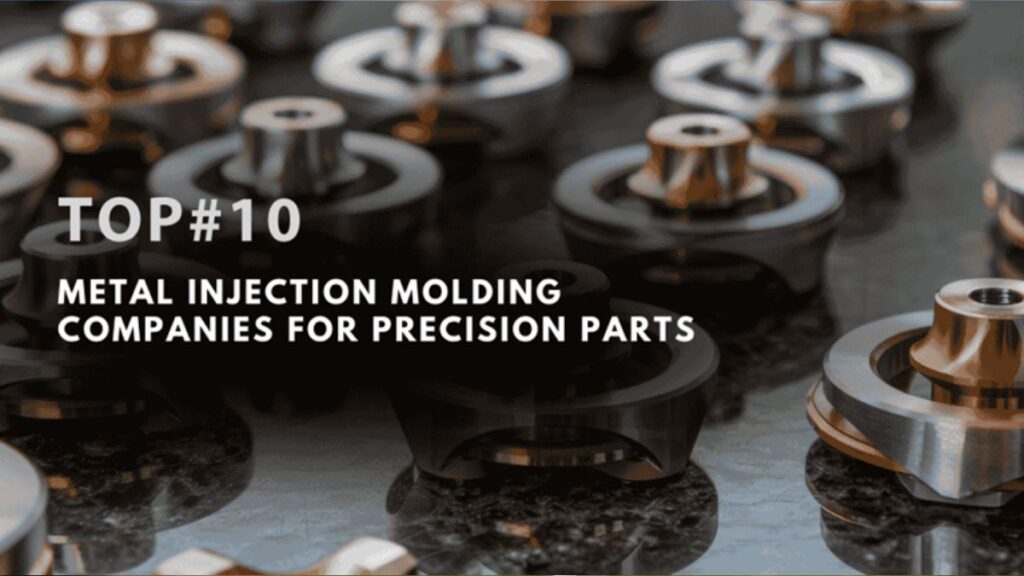

In the competitive metalworking world, the top 10 metal injection molding companies are in charge of the manufacturing of products. These industries are integrating the latest technologies like advanced automation, precision robotics, and AI into production processes. Their investment in such advanced technologies not only increases production efficiency but also improves product quality and precision levels. As a result, they can produce more complicated molded parts while reducing costs and shortening lead times. These companies are solidifying their positions as leaders in the MIM industry. Let’s discuss brief profiles about these qualifiers.

1. ProLean Tech

Established Year: 2009

Country: Shenzhen, China

Company Type: Manufacturer

Employee Size: 11-50

ProLean Tech is a Shenzhen, China-based metal injection molding (MIM) factory for intricate metal components. The company has a worldwide network and can help fulfill most of the international manufacturing requirements. Moreover, prolean specializes in manufacturing fine small metal parts with near-close dimensional tolerances. They employ a range of materials like stainless steel, titanium, tungsten as well as cobalt-chromium alloys. In addition, ProLean Tech engineers provide designing, tooling, material acquisition, and high-volume manufacturing for complex parts.

Using hi-tech MIM technology, the customers guarantee precision geometries and strict tolerance requirements are effectively met. These parts can operate optimally irrespective of the conditions in the surrounding environment.

The company serves sectors like medical, defense, automotive, and electronics. Their main products include surgical instruments, defense products, engine parts, and, automotive components, and device casings.

ProLean’s demonstrated capacity to process multi-component alloys, and the high output levels it delivers, make them the right choice for high-end MIM parts, particularly when you need Bridge Production to transition from prototype to large-scale production smoothly.

2. Redstone Manufacturing

Location: Pennsylvania, United States

Company Type: Manufacturer

Employee Size: 11-50

Established Year: 2018

Redstone Manufacturing specializes in metal injection molding-MIM and ceramic injection molding. They are mainly engaged in the manufacture of small and high-precision metal parts. The company can meet flexible demands for both volume production and complex part geometry.

The company mainly incorporates low alloy steel and stainless steel to manufacture strong corrosion-free parts. Redstone’s facilities can accommodate small-scale or large volumes depending on the client’s demand. They offer quick quotes, short delivery times, and fast integration.

In addition to its metal injection molding capabilities, Redstone Manufacturing provides design, tooling, material sourcing, and high-volume production. Their commitment to quality and innovation makes them ideal as an ideal MIM partner.

3. FOW MOULD

Year Established: 2009

Location: Zhejiang, China

Industry: Manufacturing

Fow Mould is one of the leading injection molding companies in China. They bring over 4 decades of experience in the industry and have great specialization in offering metal injection molding services. The company entails premium technologies providing comprehensive and economical solutions to their customers worldwide.

Their skilled designers and engineers ensure perfection for completing projects in various fields. Fow Mould serves industries including automobile, furniture, and warehousing businesses. Their focus is on producing only high-performance Metal Injection Molded parts.

Fow Mould’s commitment to delivering high quality makes them an ideal ally in the injection molding business.

4. MIM International

Location: Kerala, India

Company Type: Manufacturing

Employee Size: 2-10

Established Year: 2016

MIM International is an India-based company located in Thrissur, Kerala. They provide solutions for industries including medical, dental, automotive, sports, and industries manufacturing mobile phone parts. The company is engaged in the manufacture of delicate, small, and highly accurate parts or products in huge volumes.

In every project, MIM International strives for high accuracy and the possibility of achieving custom work. Their production lines are developed to suit the requirements of the various industries. As a result, they consistently deliver complex MIM parts for high-performance applications to their customers.

5. FineMIM

Year Established: 2002

Location: Jiangsu, China

Industry: Metal Injection Molding (MIM)

FineMIM is among the premier metal injection molding suppliers in China. They have been serving clients for over 12 years. The company specializes in providing quality services in manufacturing and metal processing with complicated part designs across different industries.

The advanced production facility, equipped with state-of-the-art MIM machinery, represents the company’s most sophisticated offering to date. FineMIM has a talented design and manufacturing department that can make the price for middle to large batches more reasonable. They supply their products to customers in Japan, Korea, India, the United States, and Europe.

6. Metal Powder Products, LLC (MPP)

Location: Wisconsin, United States

Company Type: Manufacturing

Employee Size: 1k-5k

Established Year: 1948

Metal Powder Products (MPP) is a global metal injection molding (MIM) industry. They provide PM and MIM parts for industries all over the world focusing on gears, sprockets, aluminum parts, and complex parts. With the objective stated in the foregoing sections, MPP is well-placed to offer the best in powder metallurgy.

MPP employs and develops state-of-the-art aluminum PM components and leads MIM technology advancements. Using CNC compaction, they produce complex components that are difficult to manufacture at other facilities. Their products are mainly employed in fluid power systems, power transmitting devices, and lightweight applications.

For over two decades, MPP has earned a prestigious place in fabricating complex metal parts and as a supplier of precision metals for mechanical and hydraulic applications.

7. Phillips Medisize

Location: United States

Company Type: Contract Design and Manufacturing Organization (CDMO)

Employee Size: 5k-10k

Established Year: 1963

Phillips Medisize is among the dominant metal injection molding companies. They focus on precision metal parts production, providing high-value, high-volume products and services for industries like medicine, automotive, industrial, defense, and electronics.

Phillips Medisize benefits greatly from the MIM process, allowing them to create complex part geometries and achieve high-quality surface finishes. One of the primary advantages of this method is its cost-effectiveness, as it can be up to 50% more efficient than traditional methods like 5-axis CNC machining. Their MIM gives near-absolute accuracy and matchless strength comparable to wrought steel in terms of mechanical properties.

Having been a contract design and manufacturing organization, Phillips Medisize provides design consultancy alongside manufacturing services. They have a detailed design procedure for manufacturing (DFM) check, gating development, and tool design with moldflow analysis.

These capabilities enable them to deliver value-added service and manage risk at every phase of production.

8. MIMfactories

Location: Taiwan

Company Type: Manufacturing

Established Year: 1981

The MIMFactories is a subsidiary of Rockleigh Industries. They have vast expertise in metal injection molding (MIM). For its 35 years of service since 1981, the company has supplied its clients with top-quality metal parts. They specialized in MIM, CNC Milling, Die Casting, and Powder Injection Molding.

The company employs Contemporary wire EDM technology as well as CAD/CAM technology. Moreover, they offer solutions from conceptualization to tool-making and their management. MIM factories process components in micro mills to a tolerance level of up to 1 micron. They use a variety of materials, including stainless steel, aluminum, and copper-based alloys.

MIMfactories’ certified products include processes like Powder Mixing and Binding, pre-press, Molding, and Sintering. MIMfactories focuses on sectors such as automotive, medical, electronics, and defense.

9. PSM Industries

Location: Los Angeles, California, USA

Company Type: Manufacturing

Employee Size: 201-500

Established Year: 1956

PSM Industries has been in the business of high-performance sintered products since 1956. They use advanced MIM technology to create components for aerospace, automotive, medical, and consumer products.

PSM provides customized solutions in engineering with a focus on quality and accuracy. They produce complex parts with close tolerances through metal powder metallurgy. They have cut down on their waste and emissions making them efficient in the large-scale production of their products.

PSM operates through seven divisions, each focusing on specialized areas such as high-performance powders, sintering, and metal injection molding.

10. Schunk Group

Location: Germany

Company Type: Manufacturing

Industry Focus: Aerospace, Automotive, Medical, and Consumer Goods

Established Year: 1913

Schunk Group is a worldwide leading company in precision components and high-performance materials with a focus on Metal Injection Molding (MIM). The company uses the best MIM technology to manufacture complex parts with small clearances for various sectors such as aerospace, automobile, and medical. Schunk has been developing solutions like the Two-Component Metal Injection Molding (2C-MIM) process.

They combine plastic injection molding and metal powder metallurgy to achieve complex geometry and high material density. MIM technology, described by Schunk has advantages: waste reduction, lower production cost, and environmental friendliness as 96% to 100% of the material is utilized.

Schunk’s quality assurance has certification from international standards that include EN 9100, IATF 16949, and ISO 9001 to ensure that high-quality products are developed.

Summary

Metal Injection Molding companies have seen significant growth globally. These manufacturers are driven by advancements in manufacturing technologies and scale economy. China, along with other global players, has firmly established itself as a key hub in this area. The aforementioned 10 companies stand out as leaders in MIM, recognized for their technological advancements, high-quality products, and professional services.

These companies provide excellence in MIM technology and produce precision parts for aerospace, automotive, medical, and consumer companies. You can choose the appropriate Metal Injection Molding company to meet your needs.