In fast-paced factories where every millisecond counts, knowing exactly where products and parts are moving keeps lines safe and running smoothly. Of all the photoelectric sensors on the market, the through-beam light curtain is often praised for its pinpoint precision, wide range, and immunity to random noise.

This post breaks down how through-beam systems work, where people are putting them to use, the benefits they bring, and what the future might hold for the technology. It’s written specifically for B2B teams such as automation builders, control engineers, equipment makers, and buyers who value high quality. For robust, accurate sensing that endures tough conditions, OMCHs family of light curtains and other photo solutions is built to answer industrial demands.

How a Through-Beam Light Curtain Works

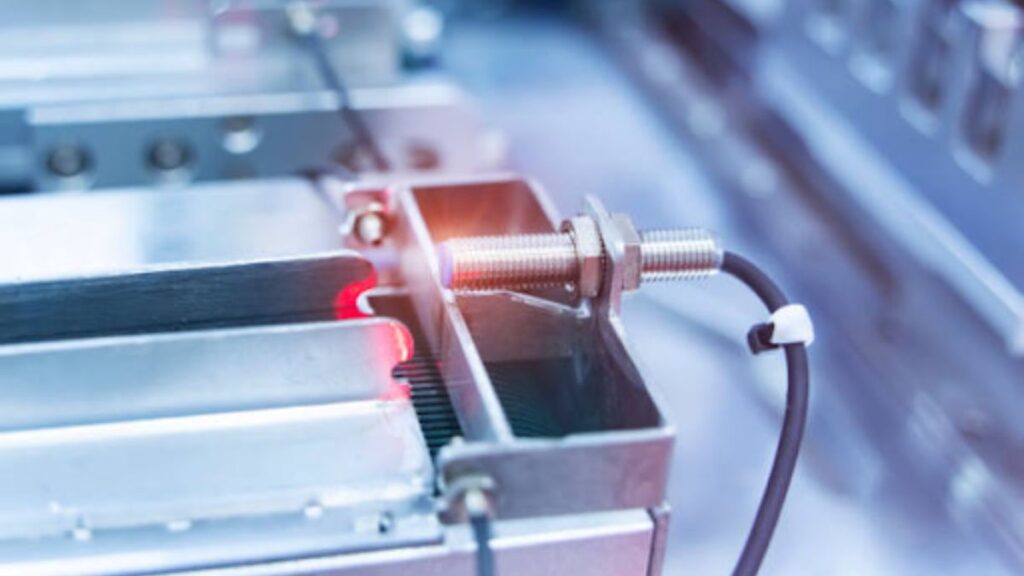

Each through-beam setup has two distinct pieces: a light emitter unit and a matching receiver. The emitter sends a narrow beam-infrared or visible-red straight across the work zone to the receiver sitting on the opposite side. When an item passes through and blocks the beam, the receiver notices the drop in light intensity and sends out its control signal.

Unlike diffuse or retro-reflective sensors, a through-beam switch sends light from one point to another, offering:

- Longest sensing distance– up to several meters

- Heaviest accuracy

- Minimal false hits from nearby objects

- Strong dust and sunlight immunity

Because of this clear path, these sensors shine in places where distant and precise detection really matter.

OMCH, a go-to name in factory sensors, builds through-beam units that mix toughness with exact readings for busy automation lines.

Industrial Uses for Through-Beam Photoelectric Switches

Manufacturers turn to through-beam sensors anytime they need fast, touch-free detection of moving items. Their simple, block-style build lets engineers mount them along conveyor belts, robotic arms, packing machines, or safety guards.

Packaging and Bottling Lines

In high-speed packing plants, through-beam switches help to:

- Spot when a bottle or can arrives or leaves

- Count products riding on the belt

- Tell quality stations to throw out poor packs

Their long reach and quick trigger keep lines flowing and stop delays before they start.

Material Handling and Logistics

In warehouses and distribution centers, through-beam sensors are set up to:

- Track packages moving down conveyors

- Notice when something blocks an automated aisle

- Work smoothly with barcode scanners and sorting arms

Because OMCH through-beam switches are so precise, even tiny boxes are spotted every time.

Automated Assembly Lines

On automotive or electronics assembly lines, these sensors help by:

- Confirming each part is in the right place and turned the right way

- Telling machines whether metal or plastic pieces are sitting in a fixture

- Sending real-time signals to robots as they pick and place items

Printing and Textile Machinery

Fast printing presses and fabric machines trust through-beam switches for:

- Detecting edges of paper or cloth

- Keeping the feed straight and centered

- Stopping jams before they damage rollers

Safety Interlocks and Light Curtains

Through-beam technology also powers many safety shields around machines. When the light beam breaks, the equipment stops at once, reducing the risk of injury.

In every setting, OMCH photoelectric sensors deliver dependable accuracy, even in tough factory environments.

Key Benefits of Through-Beam Photoelectric Switches for B2B Automation

Many B2B facilities turn to through-beam photoelectric switches to boost line efficiency, cut downtime, and tighten quality control. Here’s what these sensors add:

Extended Sensing Range

Through-beam units offer the longest reach in the photoelectric family-often over 10 meters-so they fit big conveyors or wide machinery with ease.

High Detection Accuracy

They trigger only when the light beam breaks, so stray reflections or changes in part color rarely cause false alarms.

Speedy Response Time

In fast plants, even a millisecond can matter. These sensors process signals almost instantly, keeping cycles short and moving parts steady.

Rugged and Resistant

OMCH through-beams come in tough housings that withstand:

- Dust and water (IP-rated)

- Vibrations from adjacent gear

- Electromagnetic noise (EMI)

- Caustic chemicals and wide heat swings

Lower Maintenance Load

No moving parts plus sturdy design means they ask for almost no upkeep. Physically separating the emitter from the receiver also cuts wear and makes swaps quick.

For manufacturers and system integrators, OMCH offers https://www.omchsmps.com/de/path/photoelectric-sensor/ ,head over to the OMCH product page and find tech built for the rigors of B2B work.

Tips for Choosing Through-Beam Photoelectric Switches

Picking the best through-beam sensor means looking at several details that match your project.

Beam Type and Light Source

First, decide if you need invisible infrared light or visible red light and whether a narrow or wide beam pattern works better.

Alignment and Mounting Flexibility

Getting the emitter and receiver lined up right is crucial. Choose sensors that offer alignment guides, sturdy brackets, and adjustable mounts.

Environmental Rating

In dusty, wet, or chemical areas, look for a sensor with at least IP65 or IP67 protection. OMCH models meet those tough standards.

Output Type and Integration

Check that the output fits your PLCs, relays, or microcontrollers. Common choices include:

- PNP or NPN

- Normally open or normally closed contacts

- Analog or digital signals

Cable Length and Connector Type

Select a sensor with the right cable length or standard connectors-M8 or M12-based on how the system is laid out and how easy it is to reach.

OMCH supports B2B buyers with clear data sheets, side-by-side model comparisons, and custom options tailored to each project.

The Future of Through-Beam Sensors in Smart Manufacturing

Industry lines are blending digital and physical worlds, making even basic components seem smart. Through-beam photoelectric switches once limited to simple counting are now joining the conversation.

IoT-Enabled Sensing

New models talk over networks like Modbus, PROFINET, and EtherCAT. This real-time chatter feeds predictive maintenance alerts and keeps operators in the loop.

Miniaturized and Integrated Solutions

Thanks to shrinking electronics, high-power units now fit beside collaborative robots and inside tight work cells.

Self-Calibration and Environmental Adaptation

Sensors also listen to themselves; they tweak gain when dust settles or ambient light drifts, keeping readings steady.

Energy Efficiency and Green Manufacturing

Even in plants running thousands of units, low-power firmware trims the budget and cuts carbon footprints.

OMCH is on that path, rolling out through-beam systems tailored for Industry 4.0 networks and extreme uptime.

Conclusion

For sharp, reliable detection across long spans, nothing beats the classic through-Beam Light Curtain switch. Speed, precision, and near-zero false triggers keep it essential for heavy B2B environments.

Whether they keep bottles moving on a production line or turn on a safety shield for a factory robot, through-beam sensors are key to running industry equipment at its best.

OMCH carries on that legacy by making sensors that are tough, reliable, and still able to fit new automation projects down the road.