In the arena of precision production, 5-axis Machining is a recreation-changer. It permits manufacturers to produce complicated parts with high-quality accuracy and performance. But what precisely are the axes in 5-axis Machining, and how do they work? Understanding this technique is essential to look at how the advanced generation is changing industries like aerospace, car, and medical tool production. In this text, we’ll explain the components of 5-axis Machining and how each axis facilitates high precision. Read more to get a complete view of how those axes make 5-axis machining this effective tool.

What Is 5-Axis Machining?

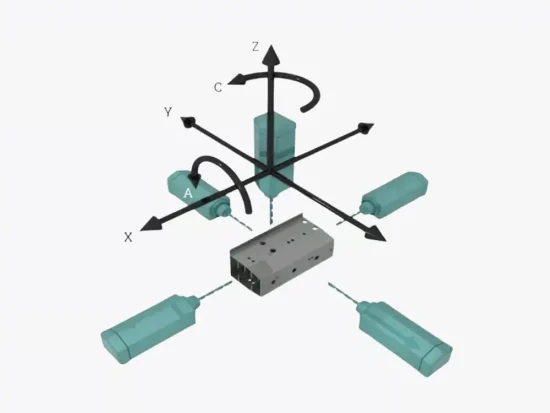

5-axis Machining is a CNC method in which tools pass five guidelines straight away. Unlike three-axis Machining, which moves alongside the X, Y, and Z axes, the 5-axis adds two greater rotational axes. This more movement permits for more complex cuts. It reduces the need for more than one setup and makes production more green.

The Basics: X, Y, and Z Axes

Let’s begin with the basics. In any CNC system, the X, Y, and Z axes shape the foundation for motion. Here’s a breakdown of each:

X-Axis: The X-axis represents horizontal movement, permitting the device to move left and proper throughout the workpiece.

Y-Axis: The Y-axis lets in a vertical motion, enabling the tool to move forward and backward.

Z-Axis: The Z-axis allows intensity management, permitting the device to move up and down.

These 3 axes allow for traditional, trustworthy cuts, making 3-axis Machining enough for less complicated projects. However, while a layout needs greater complicated geometry, such as curved surfaces or complicated contours, 3-axis Machining falls short. This is where 5-axis Machining is available, adding greater axes for exceptional flexibility.

The Added Axes: A and B (or C)

In 5-axis Machining, there are more rotational axes. These are typically called the A and B axes, but sometimes they are A and C or B and C. These axes let the tool tilt and rotate around the component, allowing the tool to attain a couple of angles without shifting the element.

A-Axis: Rotational Movement Around the X-Axis

The A-axis rotates across the X-axis. Imagine tilting the workpiece sideways. This lets the device reach the part from specific angles. The A-axis is critical for making curved surfaces, angled cuts, and complicated shapes. It’s needed in industries that require complex designs.

B-Axis: Rotational Movement Around the Y-Axis

The B-axis rotates around the Y-axis, offering another layer of movement. By permitting the workpiece to tilt in an exceptional course, the B-axis permits even more complex slicing paths and designs. The ability to rotate in each of the A and B instructions offers 5-axis machines an advantage in developing complicated 3-D surfaces and functions.

These combined moves allow manufacturers to finish intricate elements in a single setup, decreasing handling time and minimizing the chance of errors. The tool’s flexibility to approach the workpiece from nearly any perspective allows designers to create more tricky elements than ever.

Why Are 5 Axes Necessary?

Three-axis machines work well for easy parts. But they conflict with complex shapes, deep cavities, or multi-sided components. 5-axis machines add two greater rotational axes. This gives them the flexibility to make complicated designs without more setups. Here are a number of the number one motives why 5-axis Machining is vital:

1. Reduced Setup Time

With a 5-axis gadget, the element does not need to be manually repositioned for unique cuts. This streamlines the production process, permitting operators to finish complex components in a single setup, which saves time and effort.

2. Enhanced Precision

Every time a component is repositioned, there’s a risk of misalignment or human errors. 5-axis machining minimizes these dangers and supplies higher precision, particularly for designated parts that require a couple of angles or contours.

3. Complex Part Geometry

The more axes, the more manufacturers can make parts with complex designs. These can include curved surfaces, contoured edges, and angled cuts. This flexibility is essential in aerospace industries, where precision and complexity are key.

4. Improved Surface Finish

5-axis Machining reduces the need to reposition parts. This helps limit vibrations and gives smoother surfaces. It can technique the workpiece from excellent angles. This leads to exquisite finishes and much less put-up-processing.

Types of 5-Axis Machines

5-axis CNC machines are available in particular configurations, each with unique advantages depending on the mission requirements. Here’s a have a look at the primary sorts:

1. Swivel Head Machines

In swivel head machines, the reducing device rotates along the extra axes instead of the workpiece. This setup is ideal for oversized or heavy elements, as it avoids the want to reposition the fabric. Many AIXI Custom CNC Machining Services providers offer swivel head machines for initiatives wherein stability and accuracy are essential.

2. Table/Table Machines

In this kind, the workpiece rotates alongside the A and B axes. The reducing device remains stationary while the table tilts and rotates the cloth. This configuration is commonplace in industries that require precision, but it may additionally involve lighter materials.

3. Trunnion Table Machines

Trunnion table machines combine the functions of each swivel head and table/desk machine. In these structures, the table rotates around one axis while the device can rotate around every other. This setup provides stability, flexibility, and balance, making it suitable for diverse packages.

Applications of 5-Axis Machining

5-axis Machining benefits industries that want excessive precision and complicated designs.

Aerospace: It allows the making of components like turbine blades and structural components with complex shapes.

Automotive: It makes engine components, molds, and custom vehicle elements.

Medical Devices: 5-axis Machining creates precise implants, surgical equipment, and different distinct components for scientific use.

Tool and Die Making: It allows complicated molds and dies to make particular shapes quickly.

The Advantages of Choosing a 5-Axis Machining Service

Choosing an issuer like AIXI Custom CNC Machining Services has many blessings. You get access to the advanced era. You can paint complex designs. Turnaround times are quicker for distinctive components. Their specialized gadget and capabilities meet the wishes of industries that require precision and innovation.

Conclusion: The Future of Manufacturing with 5-Axis Machining

5-axis machining is a recreation changer in production. It’s rapid, precise, and may cope with complicated designs. Each axis plays a vital role in making parts with high accuracy. This era reduces setup times and improves excellent. It’s ideal for industries like aerospace and automobile, wherein precision subjects. Investing in 5-axis Machining offers you a bonus in making higher elements. Working with a 5-axis machining issuer helps convey your designs to lifestyles fast and appropriately.