CNC machining is changing manufacturing by making production faster, more accurate, and consistent. It grabs attention because it can create complex parts with ease, unlike older methods. As more businesses want better quality and less waste, CNC becomes even more appealing.

Companies see how it can lower costs, speed up work, and keep them competitive. Now is the optimal time to leverage CNC technology for enhancing your production process. Continue reading to discover how this technology is shaping the future of manufacturing.

Understanding CNC Machining

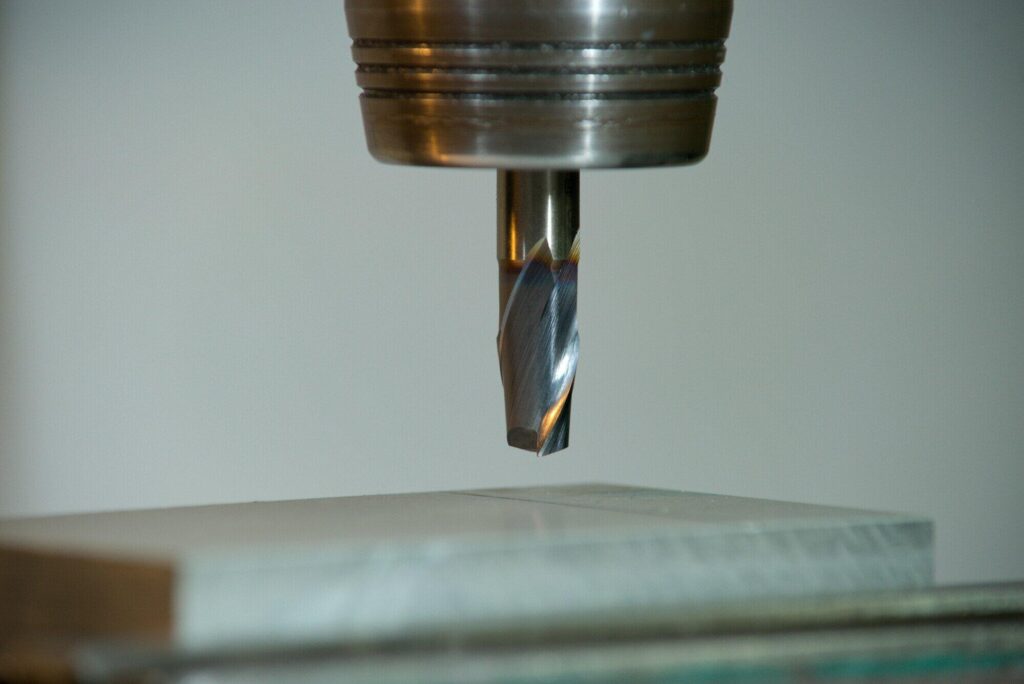

CNC, or Computer Numerical Control, is a system where machines follow computer instructions instead of being operated by hand. This makes production faster, more accurate, and more consistent. Because it removes most human error, every part comes out the same.

One big advantage of CNC is that it can make complex shapes that manual tools can’t. The computer controls every cut with high precision. This makes it useful for industries that need perfect parts, like aerospace and medical fields.

Key Benefits of CNC Machining

By using CNC machining, manufacturers gain several key benefits that boost production accuracy. It reduces human error, speeds up processes, and keeps each part consistent. These advantages help improve overall product quality and reliability.

High Precision and Consistency

CNC machines deliver parts with exact measurements every time. They reduce human error by following programmed instructions. This leads to reliable and uniform results across all batches.

Reduced Lead Times

Automation allows CNC machines to work faster than manual methods. This shortens production time and speeds up order fulfillment. Manufacturers can meet deadlines with less delay and higher efficiency.

Versatile Material Handling

CNC machines expertly cut, drill, and shape a wide variety of materials. They work with metals, plastics, wood, and composites. This versatility boosts their utility across numerous industries and products.

Cost Efficiency

The upfront cost of CNC equipment may be high, but it pays off over time. Less waste and faster production lower overall expenses. The long-term savings make CNC machining a smart investment.

Complex Design Capabilities

CNC machines can create detailed shapes that are difficult to make by hand. They handle tight angles, fine cuts, and precise features with ease. This allows manufacturers to bring more advanced designs to life.

The Importance of Reliable CNC Machining

Choosing a reliable CNC machining service is crucial because poor accuracy can cause wasted materials, expensive mistakes, and product failure. The best CNC providers use strict testing, measurements, and material checks to make sure every part meets exact standards. By partnering with a trusted machining service, manufacturers improve production accuracy and ensure higher product quality.

Moving Towards the Future

As manufacturing grows, using CNC machining will be key to staying competitive, especially with support from this awesome CNC machine shop. New tech like AI and IoT is now being added to CNC machines, making them even more powerful. Companies that adopt these tools will gain higher accuracy, faster production, and a smarter way of working.

Precision That Powers Your Production

Choosing the right CNC machining partner can shape the future of your production. With our proven expertise and focus on accuracy, you gain parts that deliver consistent performance and support long-term growth. Each project we undertake is grounded in our commitment to quality, reliability, and continuous improvement.

Allow us to be the team that enhances your manufacturing process and instills confidence for seamless scaling. Partner with us today and experience the difference that true precision can make. Keep exploring our blog for more insights that help you stay ahead in the industry.