Introduction

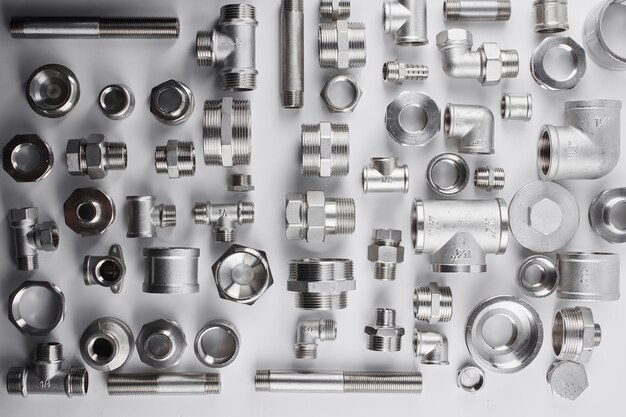

While choosing the appropriate stainless steel compression fittings for the projects that will be difficult, if you are not familiar with the elements that are influencing this decision. In different fields, including plumbing, gas distribution, and chemical processing, leak-proof connections depend on compression fittings. This article will enable you to grasp the main factors to make the best decision for your particular requirements.

1. Know Your Project Needs.

Understanding your project needs comes first in selecting the appropriate compression fittings. Think through the kind of gas or fluid that will pass through the system, the pressure values, and the temperature conditions. Although its resistance to corrosion and durability make stainless steel a popular choice, knowing the particular use will help you decide whether it is the best material and which kind of fitting you require.

2. Examine material compatibility.

Material compatibility is absolutely important since not all stainless steel fittings are made equal. Although it is common grades used in the compression fittings, 304 and 316 stainless steel have distinct corrosion resistance qualities. Although the general uses call for 304 stainless steel, 316 stainless steel is superior in settings where the fittings will come into contact with strong chemicals or saltwater. Making sure the components of your system fit will help to avoid long-term problems.

3. Think over the fitting size and thread kind.

There are several sizes and thread types of compression fittings; correct installation and operation depend on selecting the correct one. Check the fittings which is matching the measurements of pipes or the tubing that you will be attaching. Determine the type of thread NPT – National Pipe Thread, BSP – British Standard Pipe, or another standard. Incorrect size or thread type might cause leaks and system problems.

4. Review the ratings for pressure and temperature.

Every stainless steel compression fitting features particular pressure and temperature ranges. Review the manufacturer’s specs to be sure the fittings will meet your project’s requirements. Use higher pressure tolerance fittings for high-pressure systems. Likewise, if your project calls for very high temperatures, make sure the fittings can survive those levels without sacrificing their performance.

5. Search for Compliance with Standards and Certifications

Always use stainless steel compression fittings that satisfy industry requirements and certifications if you want quality and safety guaranteed. Search for fittings, for example, that satisfy ISO, ASTM, or ASME criteria. Certified fittings give you piece of mind that they will run consistently in your system since they are tested for longevity, pressure resistance, and leak avoidance.

6. Evaluate maintenance and installation ease.

Compression fitting choice also takes installation and maintenance ease of use into account. Certain fittings are made to be simpler to install and maintain by including user-friendly elements including pre-assembled components or self-sealing designs. If your project calls for regular disassembly or modification, use fittings that are readily reassembled without specific tools.

7. Evaluate Vendor Reputation and Costs

Though money is a consideration, it shouldn’t sacrifice quality. Although you should compare costs from several vendors, be sure you are obtaining premium fittings that satisfy the demands of your project. Take also into account the supplier’s reputation. Review materials, get suggestions, and select a provider well-known for offering dependable, long stainless steel compression fittings.

Selecting the correct stainless steel compression fittings for your project calls for careful thought of elements including material compatibility, size, pressure ratings, and certifications. Understanding your particular project requirements and giving quality top priority will help you to guarantee safe and effective operation of your system. Time spent choosing the appropriate fittings will save you from future system problems and expensive repairs. Recall that in every system a good and long-lasting connection depends on the correct fittings.