Environmental noise regulations have become increasingly critical in maintaining a sustainable and healthy environment. Noise pollution in industrial settings is a serious concern, impacting the surrounding community, employees, and the environment at large. To avoid fines, legal consequences, and reputational damage, companies must comply with local and international noise limits. One of the most effective ways to ensure compliance is by using industrial silencers. These devices are designed to reduce noise levels produced by industrial machinery and equipment. In this article, we’ll explore the importance of industrial silencers and how they play a vital role in adhering to environmental noise regulations.

Understanding Environmental Noise Regulations

Environmental noise regulations are designed to protect public health and well-being by minimizing the harmful effects of excessive noise exposure. These regulations vary by location but generally set limits on acceptable noise levels for different types of activities and environments, including industrial operations. Industries such as manufacturing, mining, oil and gas, and power generation are often required to meet specific noise limits to prevent disturbances to local communities and wildlife.

Non-compliance with these regulations can lead to significant penalties, fines, and legal action. In extreme cases, businesses may face forced shutdowns or public backlash. Adhering to noise regulations not only protects the environment but also ensures that companies maintain a positive reputation and avoid costly legal issues.

What Are Industrial Silencers and How Do They Work?

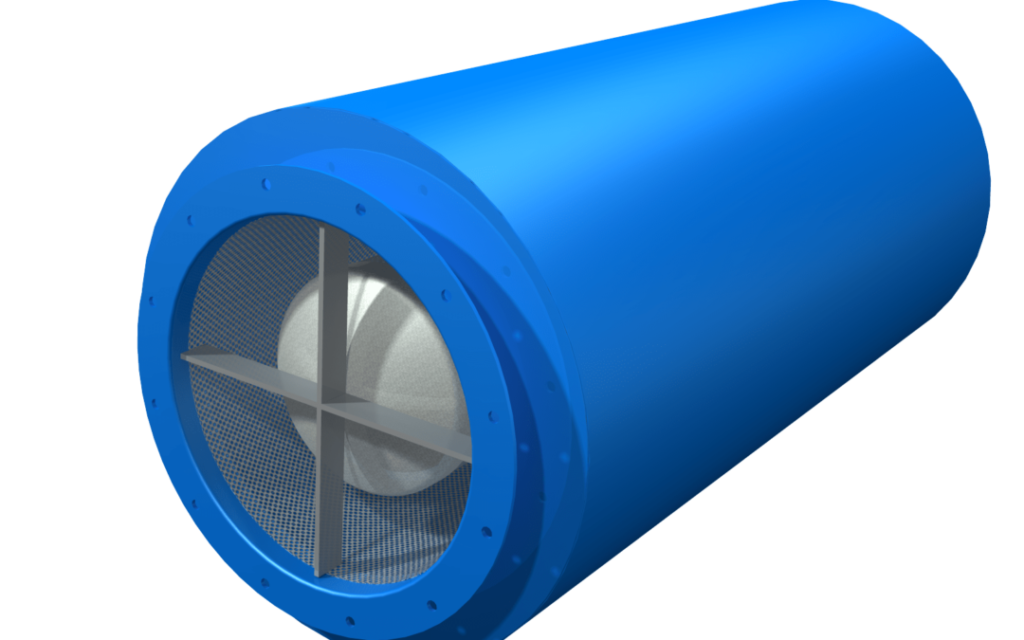

Industrial silencers are devices designed to reduce noise levels generated by industrial machinery, ventilation systems, exhaust pipes, and other equipment. They function by dissipating sound waves, absorbing noise, and deflecting sound energy away from its source. Silencers are typically installed in exhaust ducts, pipes, or ventilation systems to effectively manage noise without impacting the equipment’s overall performance.

There are several types of industrial silencers used in different settings. Vent silencers are often used to reduce noise from ventilation systems, while duct silencers are commonly employed in HVAC systems to minimize sound transmission. Engine exhaust silencers are used to reduce noise from industrial engines, while combustion silencers help control noise produced during industrial combustion processes.

By effectively controlling sound transmission, industrial silencers ensure that noise levels remain within legal limits, safeguarding businesses from non-compliance and protecting the health of workers and nearby communities.

The Impact of Industrial Silencers on Noise Compliance

Industrial silencers play a direct role in ensuring that companies remain within the limits set by environmental noise regulations. For businesses operating in noisy industries, maintaining compliance with noise restrictions is vital. Silencers help to mitigate sound levels, ensuring that machinery and equipment operate at acceptable decibel levels.

Industries that deal with high-powered machinery, such as manufacturing, oil and gas, and power plants, often require industrial silencers to meet noise limits. For instance, a power plant that burns coal or natural gas to generate electricity must use exhaust silencers to reduce the noise created by the combustion process. Without these silencers, the plant would likely exceed noise limits, which could lead to fines or legal action.

The implementation of industrial silencers not only ensures compliance but also demonstrates corporate responsibility. Reducing noise pollution contributes to a more sustainable operation and improves community relations, making the company a more attractive neighbor and business partner.

Flow Considerations in Silencer Design

While industrial silencers are primarily designed to reduce noise, it is crucial to consider the impact they have on system flow. The importance of flow considerations in industrial silencers cannot be overstated. Silencers must be designed to reduce noise without causing significant flow restrictions, as this could hinder system performance, increase energy consumption, and decrease operational efficiency.

When designing silencers, engineers must balance noise reduction with maintaining the necessary flow rates for air, gas, or liquid within industrial systems. For example, an air compressor silencer needs to dampen the sound produced by the machine while ensuring that the airflow is not obstructed, which could affect the compressor’s performance. Similarly, exhaust silencers must effectively reduce noise from engine exhaust while allowing gases to flow freely without excessive pressure loss.

Properly designed silencers allow for smooth flow and adequate noise reduction, ensuring that industrial systems operate efficiently without violating noise regulations. When choosing a silencer, businesses should prioritize models that offer both performance and noise reduction without compromising the system’s overall function.

Benefits Beyond Compliance: Why Invest in Industrial Silencers

Beyond helping companies meet noise regulations, industrial silencers provide several other benefits. One of the most important advantages is improving the health and well-being of employees. Excessive noise exposure can lead to hearing loss, stress, and other health problems for workers. By reducing noise levels, industrial silencers contribute to a safer and more comfortable workplace, which can boost productivity and morale.

Additionally, silencers have a positive impact on the environment and the surrounding community. Noise pollution can negatively affect wildlife, especially in ecosystems near industrial facilities. By using industrial silencers, businesses reduce their environmental footprint and demonstrate a commitment to sustainability.

Furthermore, industrial silencers can lead to long-term cost savings. By preventing fines and legal actions related to noise violations, companies can avoid costly penalties and litigation. Investing in silencers upfront can help businesses maintain compliance and avoid unexpected expenses down the line.

Choosing the Right Industrial Silencer for Your Needs

Selecting the right industrial silencer depends on several factors, including the type of equipment. The noise reduction requirements, and the specific industry regulations. Businesses should work with experts to assess their needs and determine the most appropriate silencer for their operations. Consulting with an experienced manufacturer or installer can ensure that the right solution is chosen to balance performance, flow, and noise reduction.

Reputable manufacturers and suppliers can provide guidance on silencer selection and installation. Businesses should prioritize working with trusted companies that offer high-quality products and professional services to ensure compliance and optimal system performance.

Conclusion

Industrial silencers play a crucial role in helping businesses meet environmental noise regulations while providing numerous other benefits. Such as improved employee health, enhanced community relations, and long-term cost savings. By understanding the importance of flow considerations and selecting the right silencer for their needs. Companies can ensure that their operations remain efficient and compliant. Investing in industrial silencers is not only a smart business decision but also a step towards a quieter, more sustainable future.